Molders face a significant challenge when making plastic parts with undercuts. Undercuts are indentations or protrusions in the parts that prevent mold from slipping away from the injection molding part's direction after it

injection molding case study - Plastic Injection Molding Company Mold Tooling Manufacturer

- You Here!

- Home Tag: injection molding case study

Introduction Flashing is a common defect in plastic injection molding industry. It typically occurs due to low melt viscosity or inefficient mold locking, resulting in material overflow on the mold surface, presenting as

With the rapid development of the mold industry in recent years, along with the continuous expansion and advancement of the application scope of new technologies and processes, there has been a qualitative change

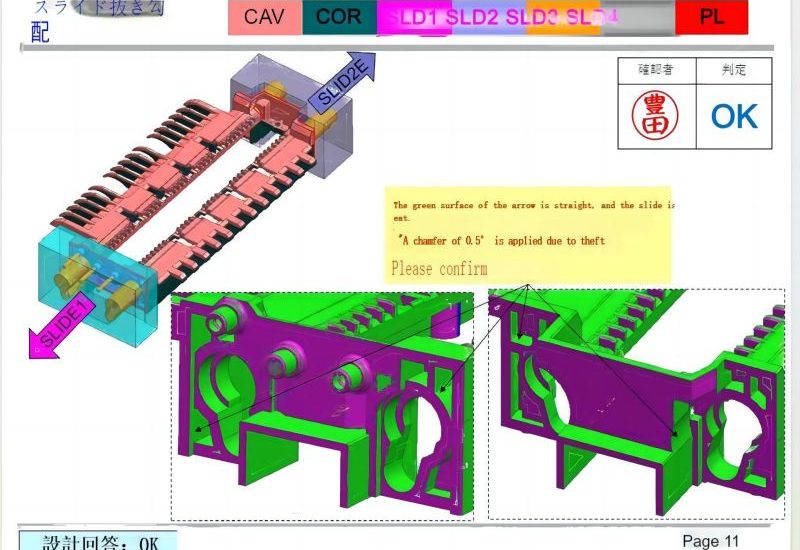

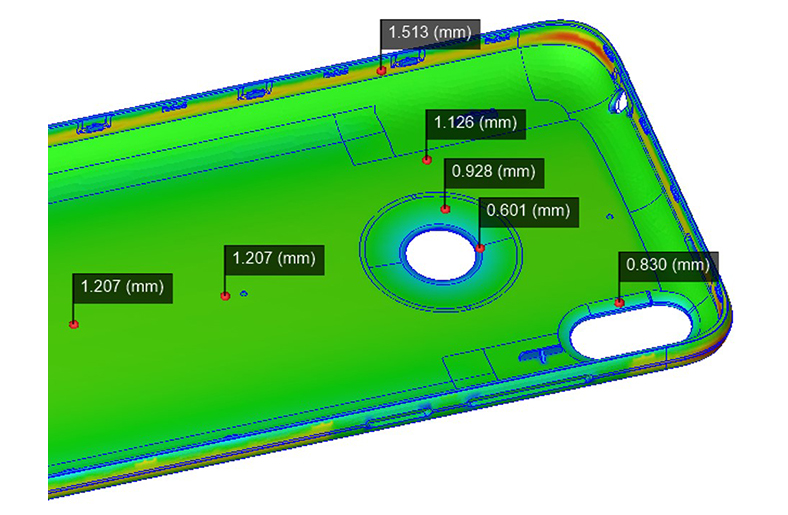

Here is cash register or checkout counter bottom base Case Study we would like to present in this page. Creating a detailed case study on plastic injection molding parts for a Japanese customer

Case sharing: Machine waveform curves that are easily overlooked The design of injection molds is one of the key steps in manufacturing high-quality plastic products. A good mold design can ensure the quality