JBR Tooling specializes in the design, development, and marketing of 2k double shot injection mold for many years. Customers from different parts of the world can avail of 2k two shot mold at a competitive rate.

- ISO-authorized company

- Oustanding quality 2k injection mold

- Strict quality inspection

- 24/7 online support

- Detailed Check List

- Fast Response

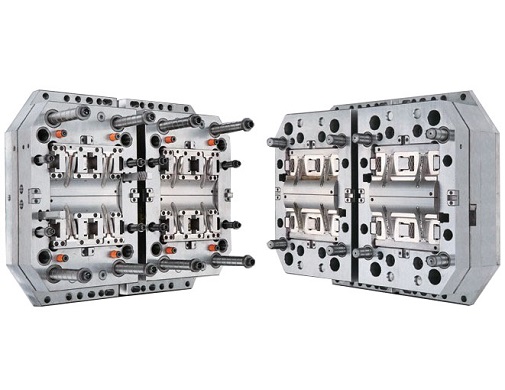

JBR Plastic Two Shot Mold

JBR Mold can help you make the double Shot injection mold and molding. We start from the parts design analysis, tooling design, tooling manufacturing through the whole project management, to parts injection and delivery.

Double Shot Injection Mold Molding optimizes co-polymerization of hard and soft materials to create powerful molecular bond. The result is a single part with production and feature advantages. It can be used for a variety of product designs across all industries. It also allows for molding using clear plastics, colored graphics and stylish finishes which improving your product functionality and marketplace value.

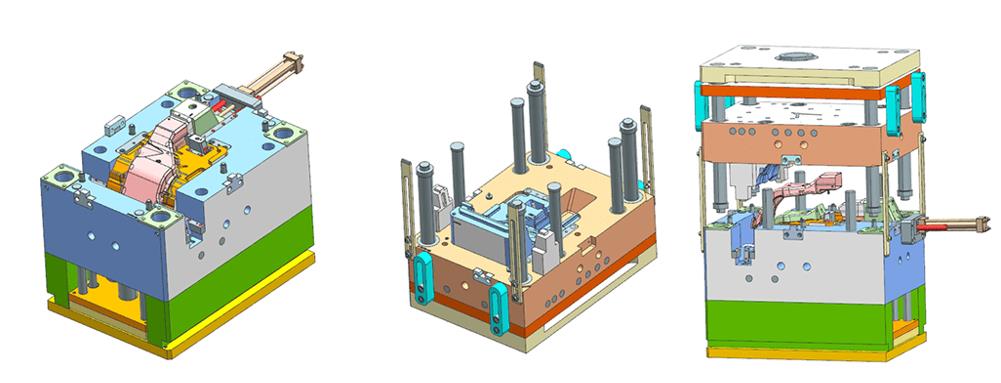

Two Shot Mold Design

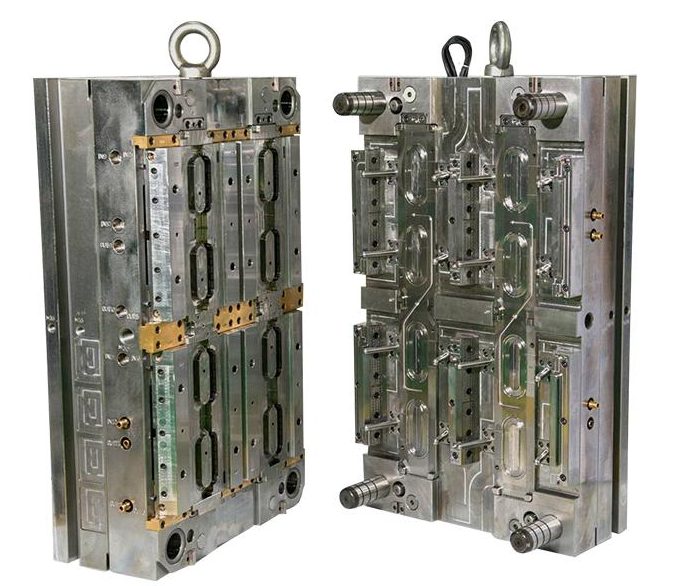

2K Double Shot injection mold design is a pivotal factor for molding success. Followings are factors that will make an influence 2k molding: dimensioning and location of the sprue gates, dimensioning of shear edges, flow aids, cooling and ejector techniques, etc. Here at JBR mold moulding factories, we keep making good 2K Double Shot mold designs and we are committed to making durable mold that is highly efficient operating and easy to make maintenance and molding production.

The followings are the points that we need to consider during 2K mold design:

- Shrinkage of plastic material

- Wall thickness

- Cavity Numbers

- Plastic material flow systems-Runner and Gate

- Cooling system for around cavity and core

- Ejection System

- Air venting

What is double shot injection molding / two shot mold molding?

Basic principles of two-color injection mold amount and over molding design. A 2K molding/two-color molding is a mold in which two different plastic materials or 2 colors are molded on the same injection molding machine, the product comes out of the mold only once. It is efficient and economical, and requires a special two-color injection molding machine. Using 2K technology can avoid possible manual assembly steps, cost advantages, design features or aesthetic preferences.

First injection hard plastic material such as (ABS、AS (SAN)、PC、PC/ABS、PE、PP、PS(HIPS,GPPS)、MBS , soft rubber for second molding, such as TPE、TPR、silicon、PVC、TPU、TPV and TPEE, the models applied to handle parts, control buttons and anti-slip applications parts, etc. ……

Transparent plastic material to do the first molding, non-transparent to do the second molding; the plastic part applied to such as electronic cigarettes.

High temperature plastic material to do the first molding, and low temperature plastic material molding temperature to do the second molding.

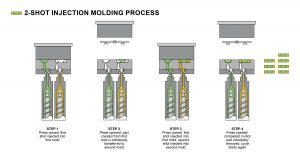

Double Shot injection Mold Molding Process

With two shot injection molding, several components can be molded with a single tool, requiring less work to produce your parts and no post-molding welding or joining of the components.

There are two phases of the two-shot molding process. The first is similar to traditional injection molding: A shot of resin is injected into a mold and cooled to form a solid part. In the second phase, the just-molded part is transferred to a second mold via a rotating platen or a robotic arm, and receives the second shot of resin – in, through or around certain parts of the first molded part, depending on the design. The two plastic resins then form a molecular bond and the multi-resin molded part is cooled and ejected.

The process isn’t difficult to understand, but it’s highly difficult to master. It requires high levels of technical expertise and attention to detail, and even the smallest mistakes can cost big money, especially in high-volume production scenarios.

That’s why it’s critical to find a highly capable supplier. Look for excellent supplier quality scorecards, defined processes to mitigate against flash, flow lines, and short-shots, and contingency plans to expand capacity as your business and your two-shot molding needs grow.

Once you find a supplier, like JBR Precision Industry Product Co., Ltd involve them early on in the design phase of your part. We can identify potential problem areas and engineer value into your product.

With double shot injection mold molding, several components can be molded with a single tool, requiring less work to produce your parts and no post-molding welding or joining of the components.

Benefits Of The Two Shot Mold Molding Process

Plastic polymers are utilized in a range of production processes, such as extrusion, compression thermoset molding, and two shot injection molding. While each is a feasible manufacturing method, many plastics manufacturers use this method due to several advantages.

In order to create the first segment of the product, one material is first injected into a mold. A second injection of a secondary material compatible with the first follows this. There are several reasons why many businesses choose to produce plastics or polymers this way.

Here are some benefits of the two shot molding process:

Versatile

Product makers prefer two shot injection molding for a variety of applications, including automotive interior parts, medical equipment, tools, and toys. It enables manufacturers to mix a multitude of components and hues to produce a robust and aesthetically pleasing product.

Materials like silicone and thermoplastics, nylon and thermoplastic elastomers, or stiff nylon and soft touch materials are a few examples of materials that can be blended successfully with this procedure.

Cost Effective

With the first mold rotated out of the way and the second mold placed around the product so that the second compatible thermoplastic can be injected into the second mold, the two-step procedure only requires one machine cycle.

The method produces more products each run for less money and requires fewer workers to produce the completed product since it uses a single machine cycle rather than multiple machine cycles. Additionally, it guarantees a solid binding between the materials, eliminating the need for later assembly.

High Product Quality

The majority of thermoplastic products benefit from two shot injection molding in numerous ways:

- Enhanced aesthetics. When products are made of different colored plastics or polymers, they look nicer and are more enticing to consumers. The product will appear more expensive if more than one color or texture is used.

- Better ergonomics. The method allows for soft touch surfaces; thus, the finished products can have handles or other ergonomically developed sections. This is crucial for tools, medical equipment, and other portable objects.

- The seal is improved when silicone polymers and other rubbery materials are used for gaskets and other parts that need a tight seal.

- It enables hard and soft polymers to produce items of the tiniest size that provide exceptional comfort and utility.

- When compared to over-molding or more conventional insert methods, it can significantly lower the number of misalignments.

- It allows producers to use several materials that can’t be efficiently bonded using other procedures to create more intricate mold patterns.

- The bond formed is incredibly strong, making the final product more robust, dependable, and long-lasting.

Conclusion

The two shot molding process helps manufactures achieve high-quality products. JBR is your all-in 2k injection mold manufacturer and supplier in China. We have over 3 decades of experience in providing standard and custom double injection mold . Yes, JBR can provide 2k two shot injection mold according to your ideas.

Allow us to be your trusted two shot mold supplier in China! We prioritize quality products and excellent services to our customers worldwide. Please let us know your project requirements! We are expert enough to handle your product development. For more information about JBR 2k double injection mold, please call us right away!