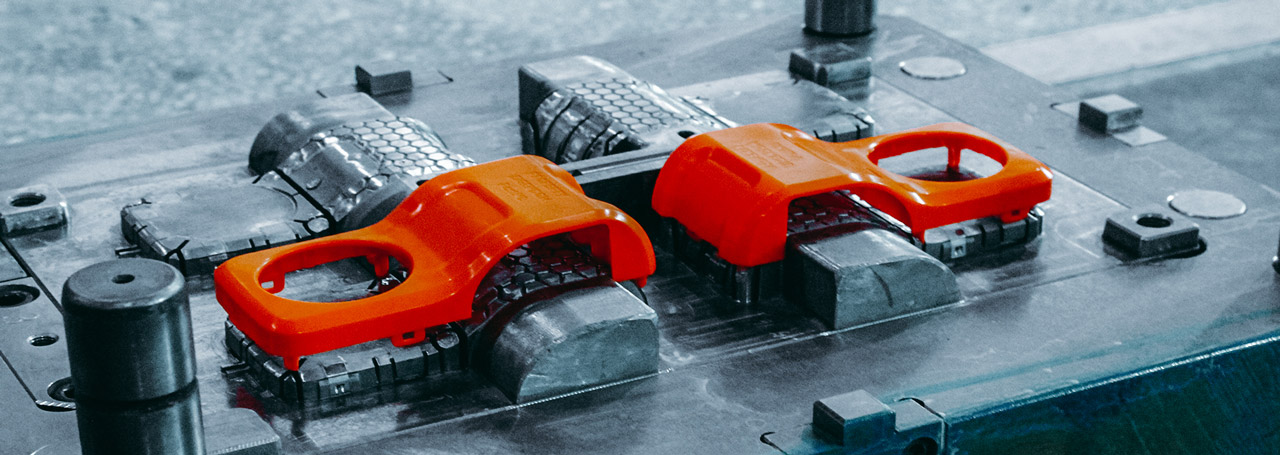

Overmolding mold services from China

Plastic overmolding mold technology is employed for a wide range of aesthetic and functional purposes in many industries and applications, such as Medical Devices, Appliances, Electronics, Consumer, Agricultural, and Automotive products and components.

A wide range of thermoplastic materials can be overmolded, including soft plastics such as urethanes and thermoplastic elastomers (TPE) and hard plastics such as nylon and polycarbonate.

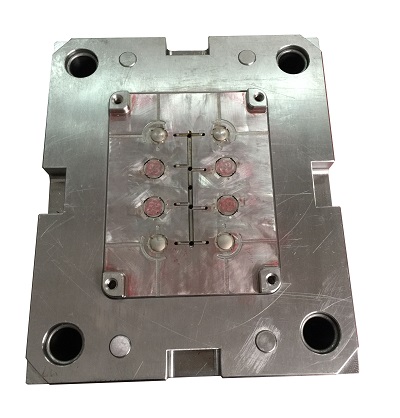

What is Overmolding Mold

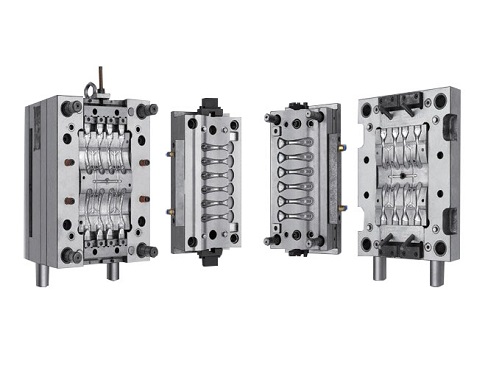

Over-molding is one of special plastic injection molding services. It bonds 2 plastic components by injection molding process. Instead of by post assembly, over-molding can provide more cosmetic & tidy plastic parts, and also being more production & cost efficiency.

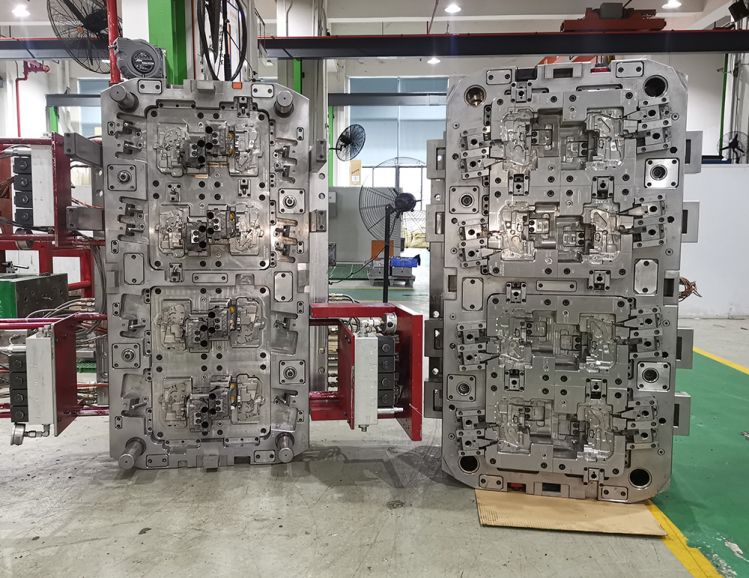

Overmolding mold is a very difficult process, requiring adherence to the very tightest of tolerances. The general concept of overmolding is quite similar to insert molding, but presents far more opportunities for mistakes and a much smaller margin of error. Welson Mold’ overmolding processes create parts specifications as tight as 0.001″. We utilize the most advanced injection molding equipment for overmolding, to ensure the highest possible quality and superb repeatability.

JBR provides over-molding service from prototyping molding to high-volume injection molding production. Our professional at over-molding material, over-molding mechanical structure, project management will guide you step by step to launch your product to market successfully.

Advantages of Overmolding Mold Service

Overmolding is a step two-process that, in some instances, may also require the use of more than one type of resin. As a result, it requires careful attention during execution as well as in the mold and product design stage. We are experienced overmolding professionals that offer these and other advantages such as:

Reduced Assembly Costs:

We offer seamless overmolding for parts that require the use of different resin materials to achieve improved stability or structural features. It is much cheaper than molding the parts separately and then assembling them at a later stage.

Flexible Use of Material:

The thermoplastic materials used in overmolding mold have to be compatible. Our team of design and engineering experts have all it takes to advise you on different material options based on your budget and the desired finished product.

Completion of Complex Parts:

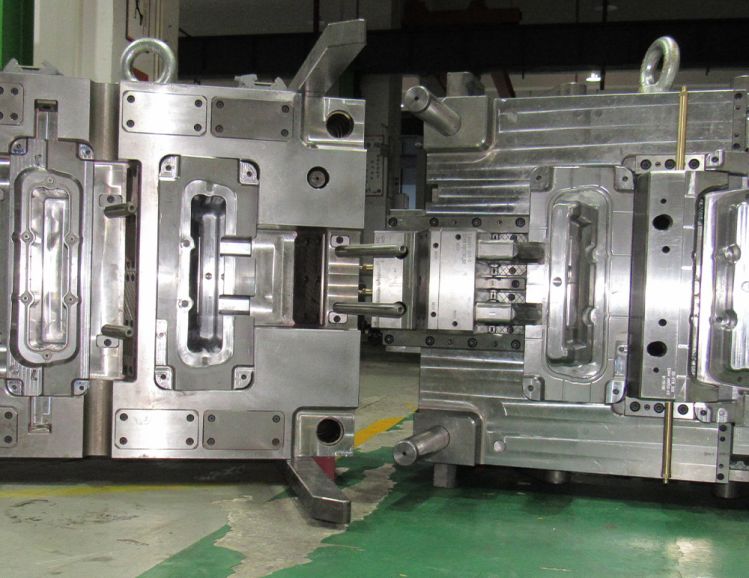

JBR Pricision Industry Product Co., Ltd factory facility is equipped with the latest overmolding equipment. This, coupled with our exceptionally talented team, enables us to achieve even the most complex designs with precision and on time.

High-Efficiency:

Our goal is to help our clients realize high-quality products while also maintaining profitability and running their businesses on schedule. To this end, we design product parts and molds that are highly optimized for the overmolding insert molding process. They are tested also for manufacturability and all-round production efficiency.

Overmolding mold Process

The overmolding injection molding process is a straightforward process. It is performed as explained below.

Clamping:

A mold comprises two parts; a core and a cavity. Clamping refers to the core being tightly secured over the cavity in preparation for the injection process.

Injection:

In this stage, molten thermoplastic material is shot into the mold structure at high pressure and predetermined temperatures. Both of these parameters will depend on the material being used as thermoplastics have different melting points and viscosities. The amount of resin that is injected is based on the design of the part and how much more resin will be injected in the second phase.

Cooling:

Once the injection is complete, the material has to be allowed to set and cool. Depending on the material, cooling aids such as water can be applied outside the mold to help quicken the process. However, because there is usually a second injection process in overmolding, the part is only allowed to cool to a certain degree.

The second injection:

When the material from the first injection has cooled enough and acquired its required shape, the second injection begins. It too involves the injection of molten thermoplastic material into the same mold at high pressure and a set temperature. The material may, nonetheless, be of a different type and color from the one used in the first injection.

The second cooling phase:

With the second layer of resin injected, the cooling process begins all over again. It may take a little longer than the first to allow the resins to fully bond and form one cohesive structure.

Ejection:

When the entire structure has cooled and is fully bonded, the mold is opened and automated ejector pins slowly push the formed part out of the mold. Draft angles play a crucial role in ensuring that ejection of the part is smooth without any bits sticking to the walls of the mold.

Overmolding Materials Option

Material options are fundamental in overmolding service. First, the chosen materials have to be suitable for the part being produced. Secondly, where more than one thermoplastic material is being used, the materials have to be compatible. Our in-house production engineering team is well-versed in resin compatibility. We also test materials to ascertain their viability with regard to manufacturing and product performance. Our list of material options includes:

| Thermoplastics | |

| ABS | PET |

| PC | PMMA |

| Nylon (PA) | POM |

| Glass Filled Nylon (PA GF) | PP |

| PC/ABS | PVC |

| PE/HDPE/LDPE | TPU |

| PEEK | |

Capacity of Overmolding Service

Maximum Part Size: 550* 350*200mm (L*W*H)

Maximum Part Weight: 1.2kg

Maximum Depth: 100mm ( 200mm if parting cross the middle of the part)

Minimum wall thickness: 0.8mm

Minimum Order quantity: 50pcs

Are you looking working on an over-molding project? Maybe with low-volume requirement for market testing. Have a contact with us now our swift response & professional over-molding services will be your reliable plastic injection molding partner.

Try JBR Now