Plastic injection molding is widely used in the production of home appliances since plastics are the primary material used in their construction. Today, plastics are so common in everyday life that the average person takes them for granted. So much so, that it is surprising for many to learn just how widespread the usage of plastics is.

Household home appliances revolutionized the way we live by extending convenience into every area of our lives, but plastics made them affordable, longer-lasting, and more versatile. Without injection molding technology, many of these parts and components would not be nearly as easy or as cost-effective to produce. Even a quick look at appliances from refrigerators to dishwashers reveals a vast array of injection molded components.

The Advantages of plastic injection molding for home appliances

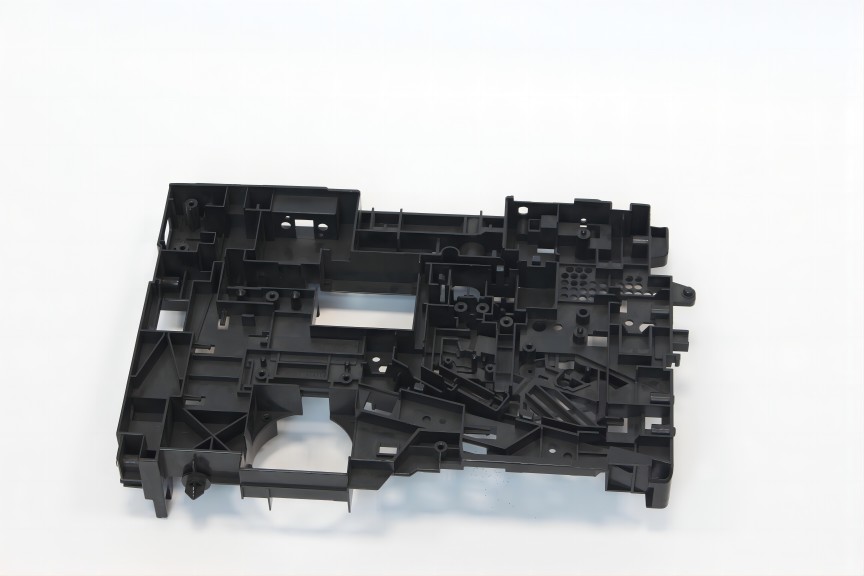

Why do so many household appliances manufacturers turn to an injection molding company to play a role in supplying plastic parts? Based on a process that uses molten plastic forced into a highly precise mold under pressure and allowed to cool, injection molding has been one of the primary means for producing plastic components for more than half a century. Highly versatile and capable of delivering several advantages over other manufacturing processes, appliances use injection molded parts for many reasons:

High-pressure injections enable plastics to reach into even the deepest parts of a mold, enabling intricate shapes and designs that minimize the need for additional processing after molding.

Molding produces a high part volume at a very rapid pace. Although the design and finalization of each mold may take some time, the household appliances manufacturing process moves very quickly afterwards. Once you have mold designs in hand, you can use them indefinitely.

Injection molding enables the easy addition of fillers for changing the properties of a plastic. Inserts and additional components inside the mold allow for even more complex processes, such as overmolding.

Plastic injection molding is a cost-effective and straightforward way to create household appliances goods. However, creating specific plastic components for household appliances without injection molding would be challenging and costly. Almost all appliance manufacturers utilize injection molding to build their plastic parts. It is a very repeatable method. Some of the appliances you’ll find in your house made using this technology are listed below.

Fridge Components

Plastic is used in a wide variety of products, including fridge holders, storage jars, and condiments, to name a few.

Plastic injection molding Kitchen Tools

There are a lot of kitchen devices that are created out of plastic components. The inside of the toaster is built from the plastic mold for specific devices. Additionally, plastic injection molding and packing containers are used to construct the blender container.

Dishwasher Components

Injection molding is used to make the inside parts of contemporary dishwashers. Dish racks may also be manufactured from the same material.

What are the Merits of Plastic Injection Molding in Home Appliances?

Most home appliances employ injection molding to produce most of their plastic components. It signifies that there are several benefits to the procedure. Plastics may be injected into an object with injection molding, making it possible to create complex patterns and forms that don’t need further molding steps.

Injection molding allows for easy modification of the plastic’s characteristics by adding additional fillers. In addition, the mold’s inserts and attachments allow for a more complex operation like remolding. Molding plastics in an injection mold involves rapidly moving a huge amount of material. Plastic components for appliances are manufactured quickly, even if the design and final stage may take some time.

The plastic injection molding process utilized in home appliances has been explained. Appliances for the kitchen, such as refrigerators and dishwashers, are all created using this technology. This is the most common technique for producing plastic parts for appliances.

If you have any queries about injection molding for plastic components for appliances, please do not hesitate to contact us today.