Molders face a significant challenge when making plastic parts with undercuts. Undercuts are indentations or protrusions in the parts that prevent mold from slipping away from the injection molding part's direction after it

Plastic Injection Technical Mold Tooling Manufacturer China

- You Here!

- Home Category: Plastic Injection Technical

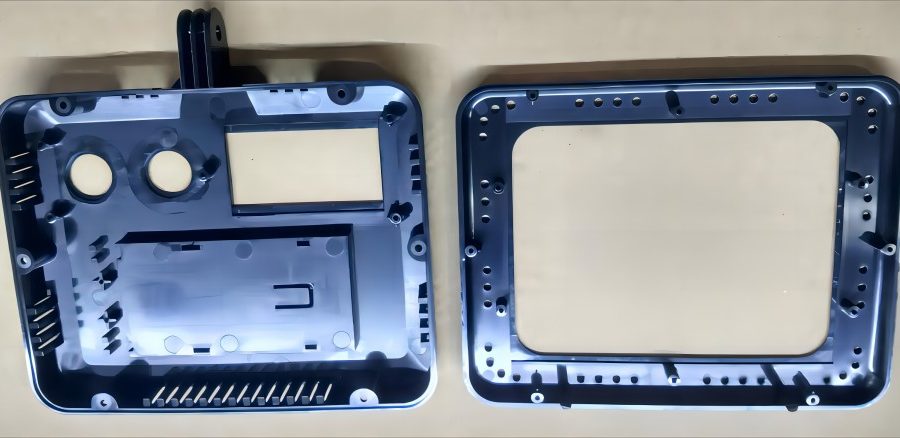

This paper discusses the impact of poor exhaust and mold plate expansion deformation on products, proposing an idea to control the distribution of injection molds pressure by changing the number and distribution of

In modern medicine field, safe, reliable, and efficient storage solutions for medication are crucial and necessary. Medical-grade injection molding plastic pill boxes play a key role in this regard. By leveraging advanced technologies,

Photography lighting equipment is crucial for achieving professional-quality images. We will explore the role of injection molding in the manufacturing of photography light parts and how JBR Mold excels in this domain. Understanding

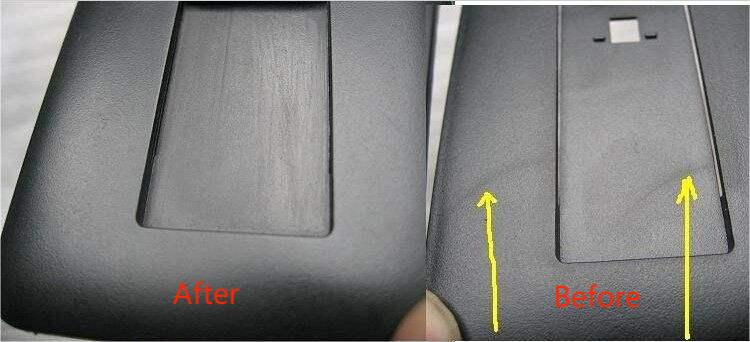

In plastic moulding parts products, especially those made from ABS, PP, and PC, it is common to see shiny stress marks on the surface. These include ejector pin stress marks, insert stress marks,

Introduction Flashing is a common defect in plastic injection molding industry. It typically occurs due to low melt viscosity or inefficient mold locking, resulting in material overflow on the mold surface, presenting as

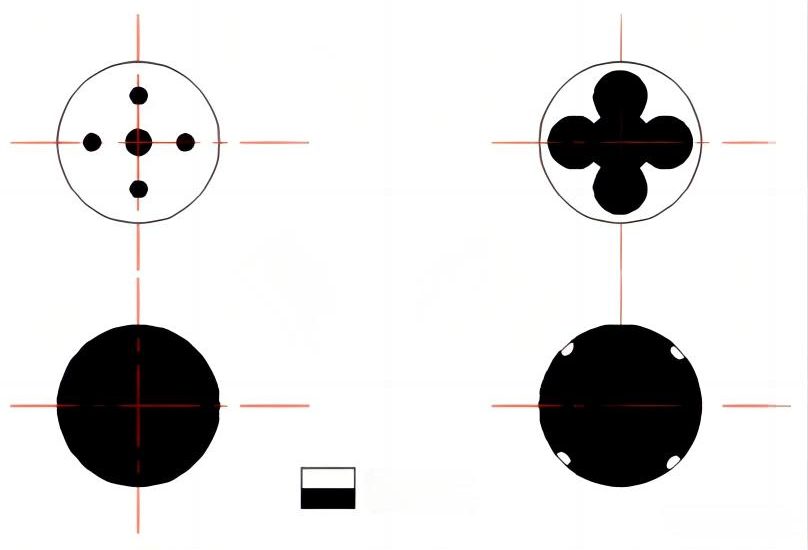

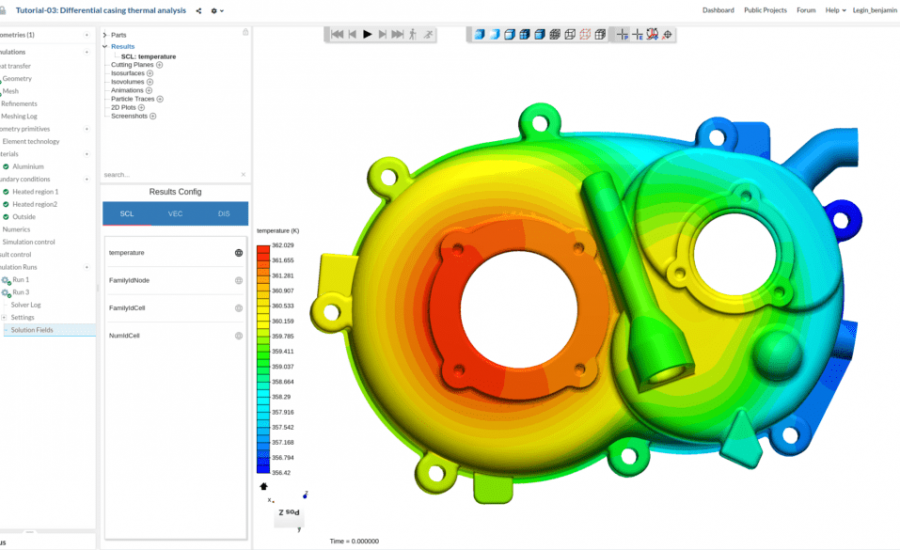

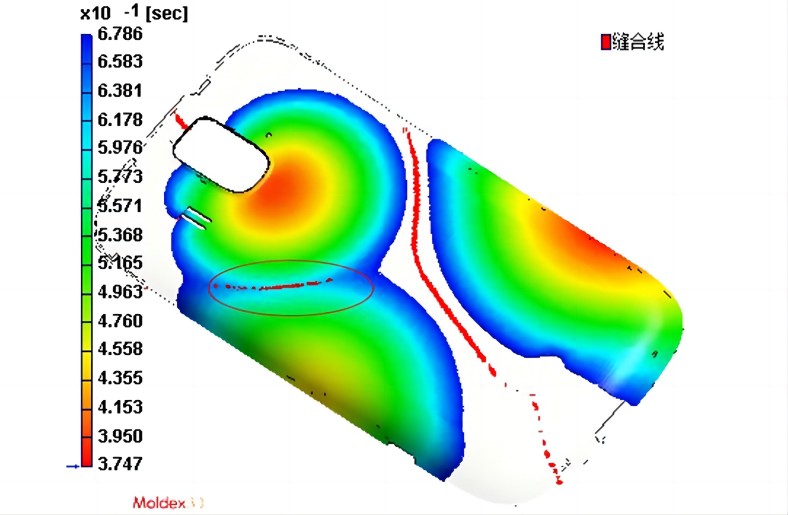

Injection Mold Computer-aided engineering (CAE) is the practice of applying computer-assisted math-based analysis and simulation techniques to the product development process. Computer-Aided Engineering (CAE) is a broad term that refers to the use

As a Plastic Injection Molding factory Molder, My pleasure to share CAE which help you to detect the injection molding products or parts appearance problems. Preface Since I have been engaged in the