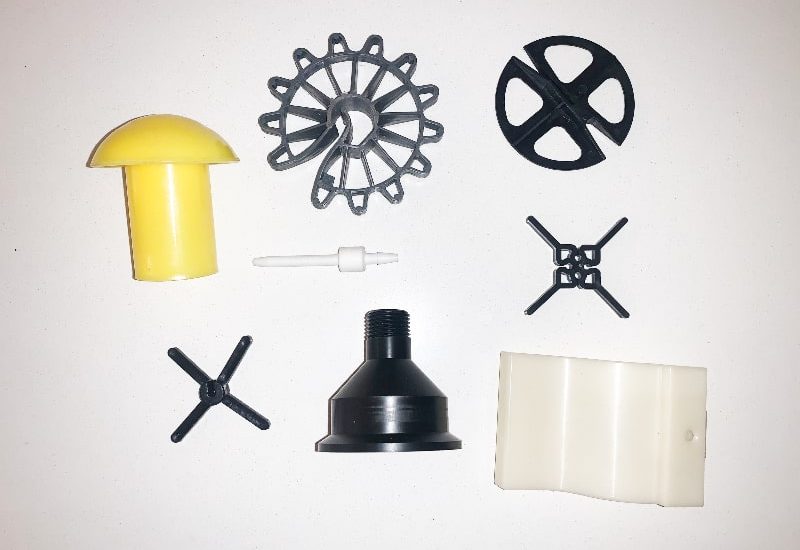

Molders face a significant challenge when making plastic parts with undercuts. Undercuts are indentations or protrusions in the parts that prevent mold from slipping away from the injection molding part's direction after it

Plastic Knowledge - Plastic Injection Molding Company Mold Tooling Manufacturer

- You Here!

- Home Category: Plastic Knowledge

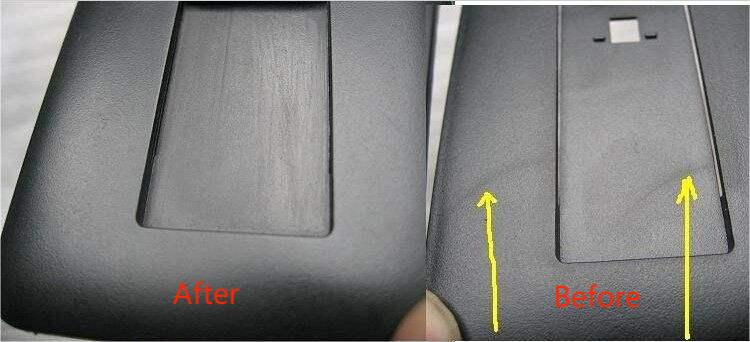

In plastic moulding parts products, especially those made from ABS, PP, and PC, it is common to see shiny stress marks on the surface. These include ejector pin stress marks, insert stress marks,

With the rapid development of the mold industry in recent years, along with the continuous expansion and advancement of the application scope of new technologies and processes, there has been a qualitative change

In the world of biobased and biodegradable injection molding resins, the newest kid on the block is polyhydroxyalkanoates (PHA). It has been used for extrusion for some time in the manufacture of straws

Registration is open for the next round of Career Ambassador training organised by the British Plastics Federation (BPF). The Career Ambassadors initiative equips people working within the plastics industry with the skills they

Here is cash register or checkout counter bottom base Case Study we would like to present in this page. Creating a detailed case study on plastic injection molding parts for a Japanese customer

One of our primary plastic molding services, thermoset injection molding results in high-quality components that meet tight tolerance requirements and stringent industry demands. Unlike thermoplastic molding processes that are easily reversible, thermoset molding

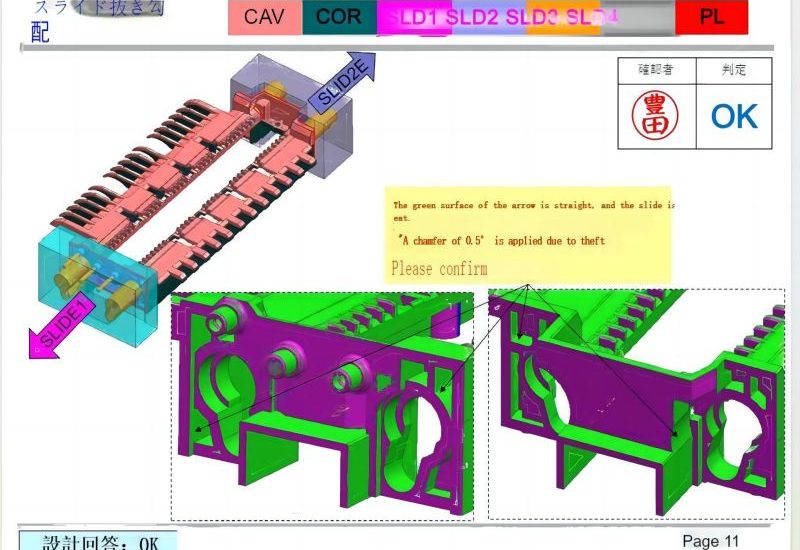

Case sharing: Machine waveform curves that are easily overlooked The design of injection molds is one of the key steps in manufacturing high-quality plastic products. A good mold design can ensure the quality

- 1

- 2