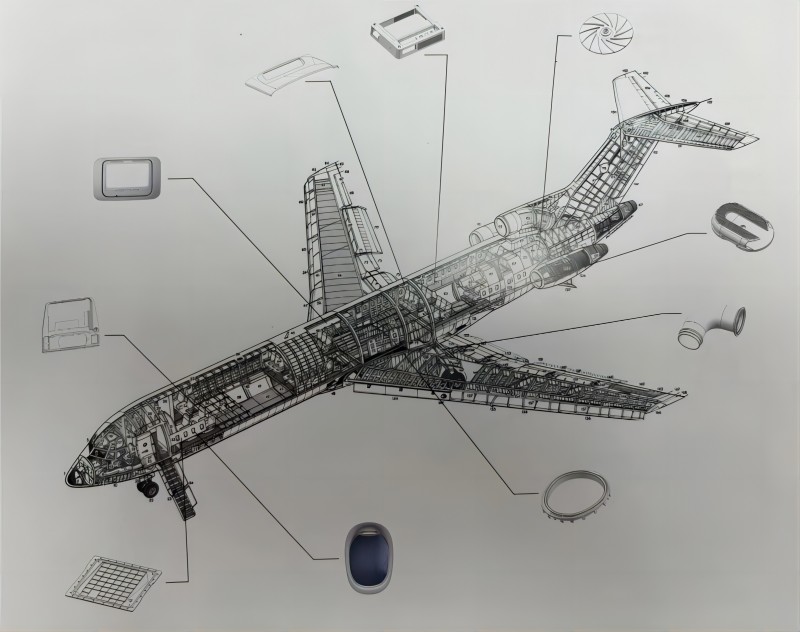

JBR offers High-quality some common aerospace plastic injection molding components include micro gears, bearings, lenses, and sensor components in Aviation Industry. Plastic injection molding allows for the production of customized components tailored to specific aerospace applications, offering flexibility in design and material selection to meet the requirements of different aircraft models and configurations.

Technical understanding and high performance are essential for the high demands placed on materials and solutions in the aerospace industry. With years of experience in high-performance and engineering thermoplastics for aerospace, JBR is well positioned to find the right solution for any challenge.

Injection molded parts used in the aerospace industry must be manufactured with the highest precision and accuracy to ensure the highest safety and performance requirements. Injection molding is one of the most common manufacturing processes for this purpose in combination with plastics used in aircraft construction.

Common Injection Molded Aerospace Products

JBR only offers some common high-quality aviation aerospace plastic injection molding components include micro gears, bearings, lenses, and sensor components. Injection molding is incredibly useful for aerospace engineers. Some common aerospace products are as follows:

Aerospace plastic injection molding Battery Housings

Battery housings are usually plastic components that hold the electric cells and fluids powering the electronics inside the aircraft. Injection molding allows manufacturing housings with appropriate strength to contain battery components and sustain in-flight vibrations without damaging the battery components. Moreover, designers have the liberty to choose plastics with high chemical resistance to withstand the acidic battery environment.

Circuit Enclosures

Enclosures in aircraft have more stringent requirements than regular electronic enclosures. Besides, holding circuitry in place, they must also protect them from in-flight impulse and cycling vibrations, which have the potential to damage the circuitry inside. Moreover, plastic is a good electric insulator, making it suitable for this application.

Aerospace plastic injection molding Radomes

Radomes are enclosures to protect signal transmission and radio communication equipment from electrical interference and bad weather. Due to this, thermoplastics like fluoropolymers have ideal material properties for this application.

Pilot Tubes

These are very useful sensing devices that provide pilots with crucial information on flow speed. They must have a smooth surface finish, so the airflow is not disrupted, which is one of the strengths of injection molding. Furthermore, with injection molding, engineers can select a plastic that can withstand the cold temperatures at high altitudes (since pitot tubes are exposed to the environment).

Aviation Industry Turbine Blades

Plastic turbine blades are a great way to reduce weight in smaller aircraft like drones and model planes. Injection molding gives them the desired strength and surface finish to allow proper propulsion of the Aviation Industry.

Aviation Industry Chassis Parts

Plastic chassis parts are common in drones and small-scale, low-performing products. Manufacturing engineers prefer injection molding for chassis parts due to its high strength and fine surface finish. Moreover, an aircraft has hundreds of chassis components, and it is cheaper to mass produce with injection molding, offering a significant economic advantage for Aviation Industry.

Aerospace plastic injection molding Bezels

Window bezels must be airtight and have high manufacturing tolerance to completely seal the aircraft from air leakage. They are non-load bearing components, so it makes engineering sense to manufacture them from lightweight plastic materials.

JBR is here to assist you in your manufacturing projects. For more information on how we can help you meet your business needs, feel free to contact us!

What is smart manufacturing in aerospace and defense?

Smart manufacturing in aerospace and defense involves updating production processes to increase efficiency and reduce risk. It starts with connecting engineering to the shop floor with a model-based manufacturing plan. Leverage a digital twin to validate that plan virtually before physical commissioning. Finally, implement advanced manufacturing technologies to help continuously optimize products and processes.