The JBR Plastic Injection Molding Team is likely a specialized group within JBR, a company or organization involved in plastic injection molding. Here’s how such a team might be structured and what roles its members could have:

Chen Liang

Steven Liang

Norman Xie

Jack Li

Jessica Yang

Ason Zhong

Plastic Injection Molding Team Project Manager:

Oversees the entire plastic injection molding project, from initial concept to final production. Coordinates with other departments, sets timelines, and ensures that project goals are met within budget and schedule constraints.

Design Engineers:

Responsible for designing the molds and ensuring that they meet the specifications required for the injection molding process. They use CAD software to create 3D models and simulations to optimize the design for manufacturability.

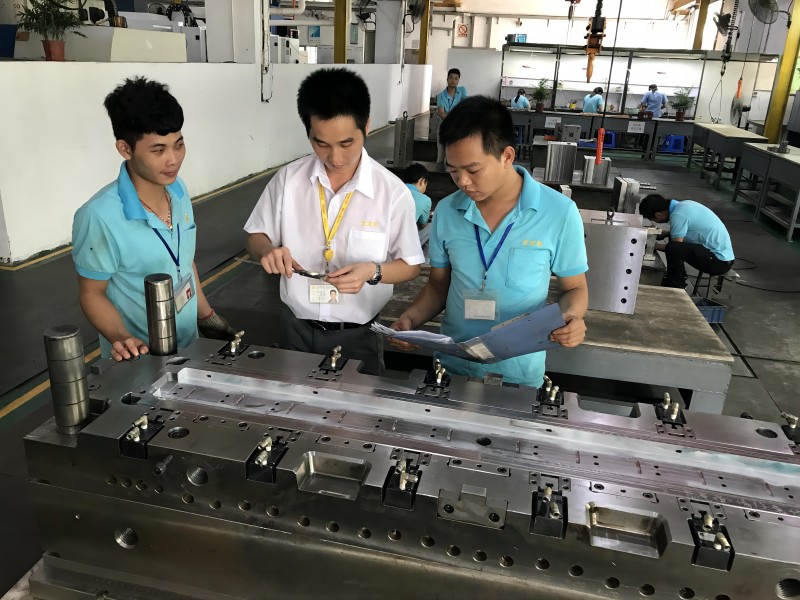

Tooling Engineers:

Design and oversee the fabrication of the molds used in the injection molding process. They work closely with design engineers to ensure that the molds are manufactured to the required specifications and quality standards.

Project Process Engineers:

Develop and optimize the injection molding mold making process parameters to achieve the desired quality, efficiency, and cycle times. They troubleshoot any issues that arise during production and implement corrective actions to improve process performance.

Plastic Injection Molding Team Quality Control Inspectors:

Responsible for inspecting the molded parts to ensure that they meet the required quality standards and specifications. They perform visual inspections, dimensional measurements, and other tests to verify part quality and identify any defects.

Machine Operators:

Operate the injection molding mold making machines and oversee the production process. They monitor equipment performance, troubleshoot any issues that arise, and ensure that production runs smoothly and efficiently.

Material Handlers:

Responsible for handling and preparing the raw materials used in the injection molding process. They load the materials into the machines, monitor material levels, and ensure that the correct materials are used for each production run.

Maintenance Technicians:

Maintain and repair the mold making injection molding equipment to ensure that it operates safely and efficiently. They perform regular preventive maintenance tasks, troubleshoot equipment issues, and make repairs as needed to minimize downtime.

Logistics and Supply Chain Specialists:

Coordinate the logistics of raw materials and finished products, ensuring that materials are ordered and delivered on time and that finished products are shipped to customers according to schedule.

Plastic Injection Molding Team Safety and Compliance Officers:

Ensure that all safety regulations and compliance standards are met within the injection molding facility. They conduct safety inspections, provide training to employees, and implement safety protocols to prevent accidents and injuries.

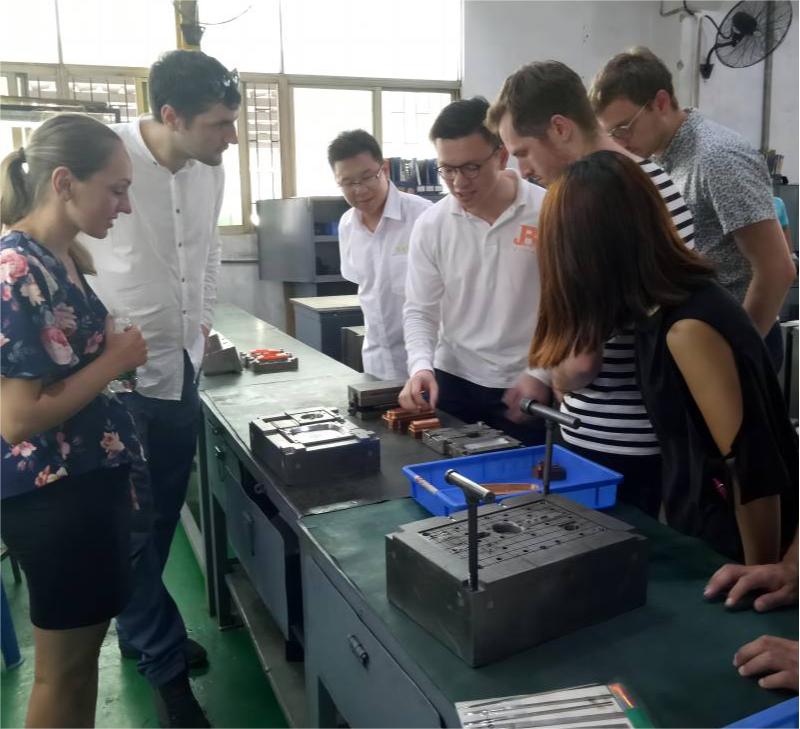

By having a dedicated team with diverse skills and expertise, JBR can effectively manage all aspects of the plastic injection molding process, from design and tooling to production and quality control, ensuring high-quality products are delivered to customers on time and within budget.

Clients are encouraged to visit our factory

In summary, a Professional Mold Making Plastic Injection Molding Team plays a critical role in ensuring the success of plastic injection molding projects. Their expertise, innovation, precision, efficiency, collaboration, commitment to quality, and dedication to continuous improvement are essential for delivering superior molds that meet the needs of customers and drive overall project success.