China JBR Insert Injection Mold Service

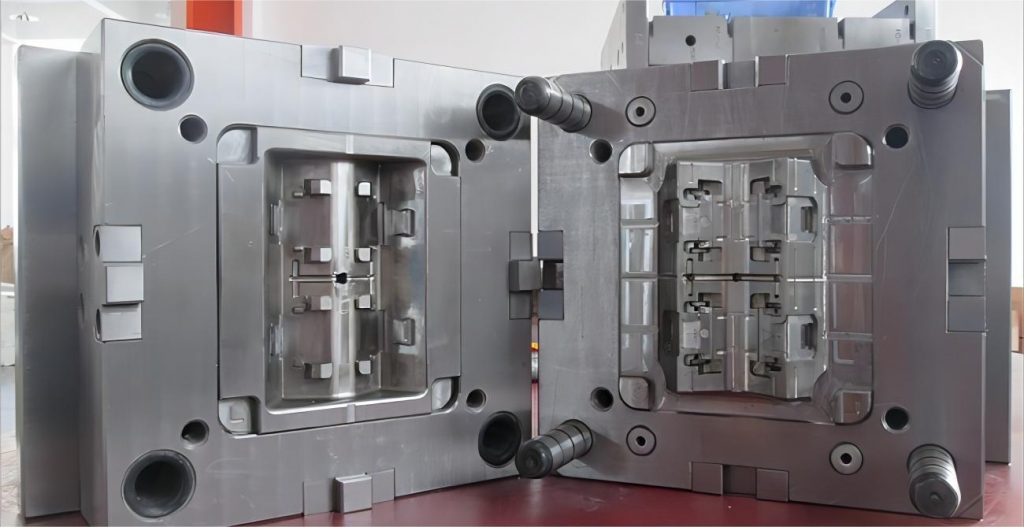

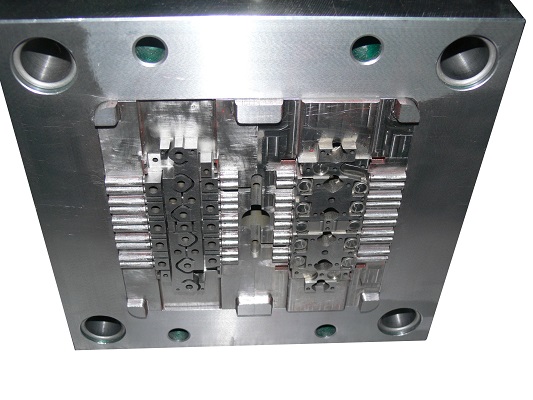

utilizes highly-advanced vertical molding machines that are specifically designed for insert injection molding. The insert molding service process requires very tight tolerances to ensure correct formation of the plastic parts misalignment of even a fraction of a millimeter can lead to complete failure of the process. Our state-of-the-art insert molding equipment can meet even the most exacting specifications.

To guarantee that the metal insert mold parts match these specifications, as well, we’ve forged sound working relationships with a number of vendors who supply us with high quality metal insert components. Our customers can supply their own inserts, as well.

Saving time and saving money are vital keys to growing your business and your profits. Insert molding streamlines production and helps eliminate the need for additional secondary operations, making it faster and cheaper to produce a finished complex product.

Additional advantages of metal insert mold and insert molding service

- Consistency: Inserts add part consistency by eliminating operator error.

- Reduced assembly and labor costs:Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths.

- Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths.

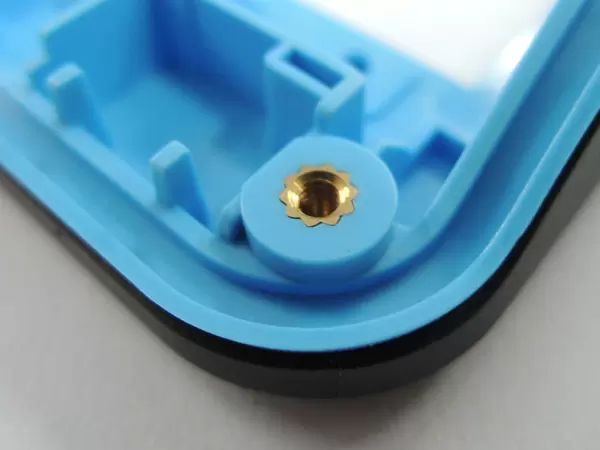

- Reduced size and weight: By eliminating fasteners and connectors, and by combining the physical strength of resin and metal inserts, insert molding yields smaller and lighter components.

- Increased reliability:With every part tightly secured in thermoplastic, an insert molded component prevents part loosening, misalignment, improper terminations, and other problems. The thermoplastic resin also provides improved resistance to shock and vibration.

- Increased design flexibility:Designers appreciate the virtually unlimited configurations that insert molding allows. For example, in creating a 3D circuit board, overmolding permits circuitry to move freely through the part, from inside to outside, up walls, down in holes-and the plastic ties it all together.

Insert Molding Service Applications

Current custom insert molding applications are wide ranging, with few limitations on material combinations, including:

- Medical devices and instruments, such as needle hubs and tube valves

- Knobs for appliances, controls and assemblies

- Encapsulated electronic devices and electrical components

- Military equipment

- Threaded fasteners

- Encapsulated bushings, tubes, studs and posted

Do you want to check

related products?

Insert Molding Service Applications and Materials

Engineering plastic or Thermo Plastic Rubber (TPR) inserted with metal frame die casting, plated copper pin, sockets, wire frames, etc.

- TPR + Metal Frame(3C Mechanical Parts)

- ABS + Al. Die Cast (Sports/ Medical)

- Eng. Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector)

- Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)

Matel Insert Mold Molded Parts

Conclusion

Insert molding is a key fabrication process across many industries and offers a wealth of benefits. JBR is a full-service, custom injection molding provider that works with a variety of high-performance engineered thermoplastics. We operate the latest automation and molding equipment, which allows us to compete on an international scale. Contact us today to learn more about our insert molding services, or request a quote to get started on your solution.