Certifications are a testament to a plastic injection molding manufacturer‘s commitment to quality, safety, and compliance with industry standards. Here are some key certifications that a reputable manufacturer might hold:

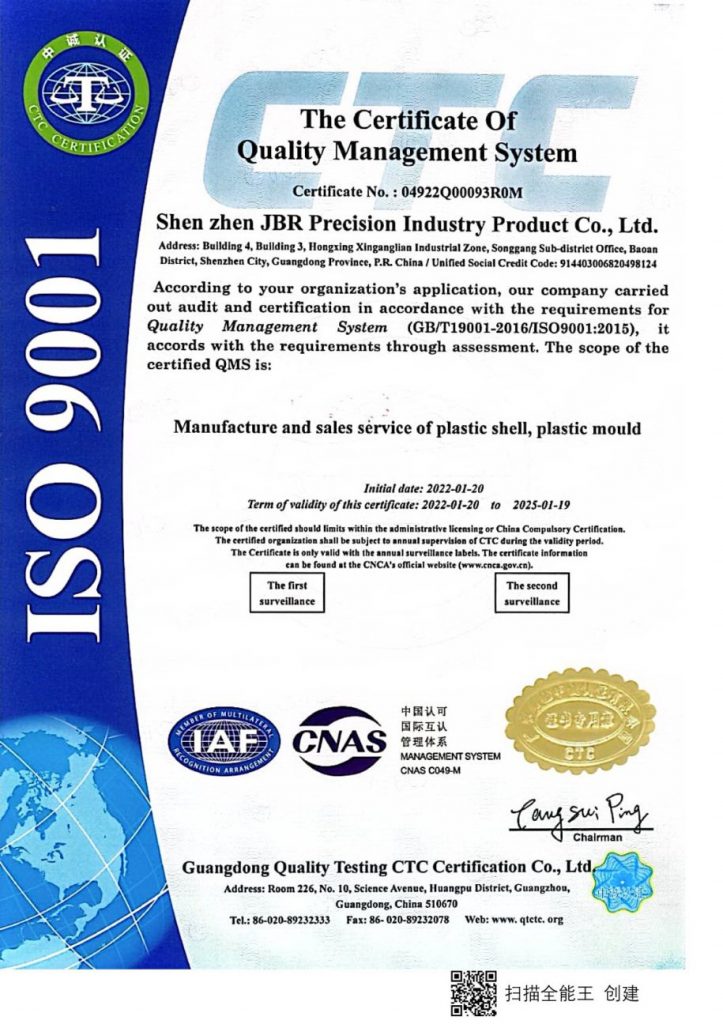

ISO 9001:2015:

This certification sets out the criteria for a quality management system and is based on a number of quality management principles including a strong customer focus, the involvement of top management, and continuous improvement. It ensures that the manufacturer has robust quality management processes in place to consistently deliver products and services that meet customer and regulatory requirements.

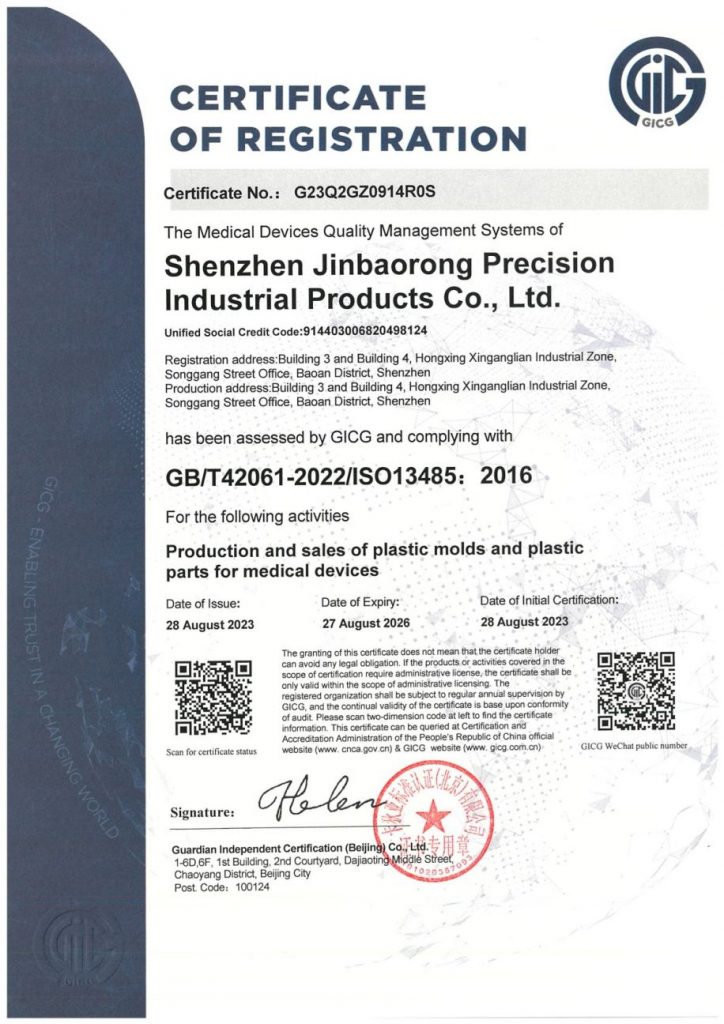

ISO 13485:2016:

If the manufacturer produces medical devices or components, ISO 13485 certification is essential. This standard specifies requirements for a quality management system where an organization needs to demonstrate its ability to provide medical devices and related services that consistently meet customer and applicable regulatory requirements.

ISO 14001:2015:

Environmental management is becoming increasingly important in manufacturing. ISO 14001 certification demonstrates that the manufacturer has an effective environmental management system in place, minimizing environmental impact, reducing waste, and ensuring compliance with environmental regulations.

IATF 16949:2016:

If the manufacturer serves the automotive industry, IATF 16949 certification is crucial. It defines the quality management system requirements for the design and development, production, and, when relevant, installation and service of automotive-related products.

UL Certification:

UL (Underwriters Laboratories) certification ensures that the manufacturer’s products meet safety and performance standards set by UL. This certification is particularly important for products intended for markets like North America.

FDA Registration:

If the manufacturer produces components or products for the food and beverage industry or medical devices, FDA registration is necessary. It ensures compliance with regulations set by the U.S. Food and Drug Administration for safety and quality.

RoHS Compliance:

RoHS (Restriction of Hazardous Substances) compliance ensures that the manufacturer’s products do not contain restricted substances such as lead, mercury, cadmium, and others, which are harmful to the environment and human health.

REACH Compliance:

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) compliance is essential for products sold in the European Union. It ensures that the manufacturer’s products comply with regulations regarding the registration, evaluation, and restriction of chemical substances.

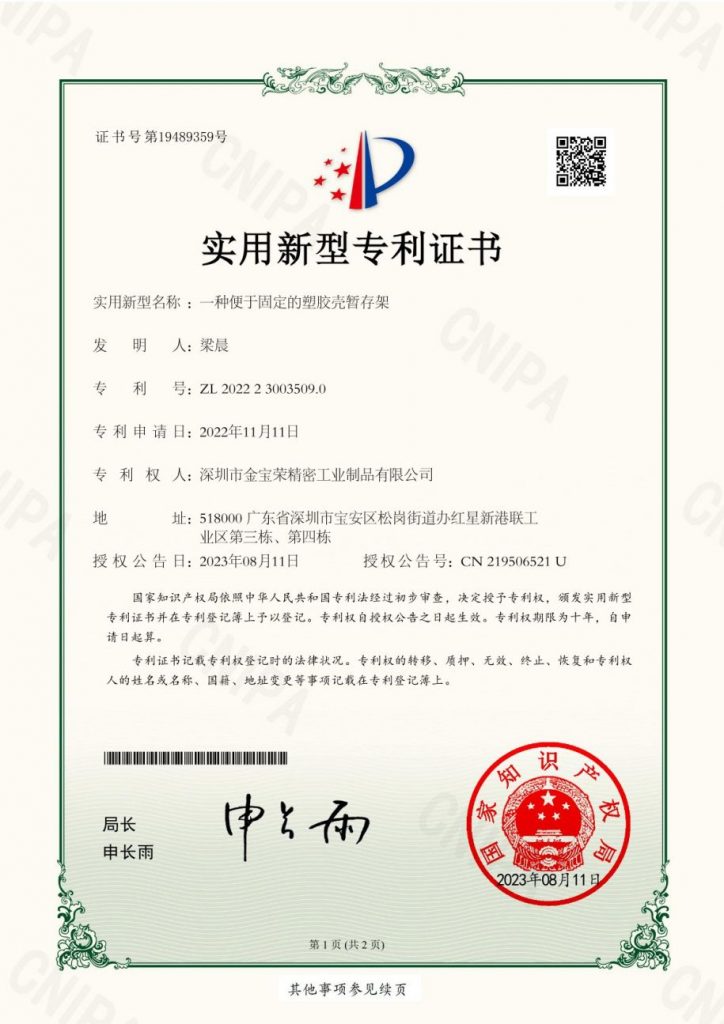

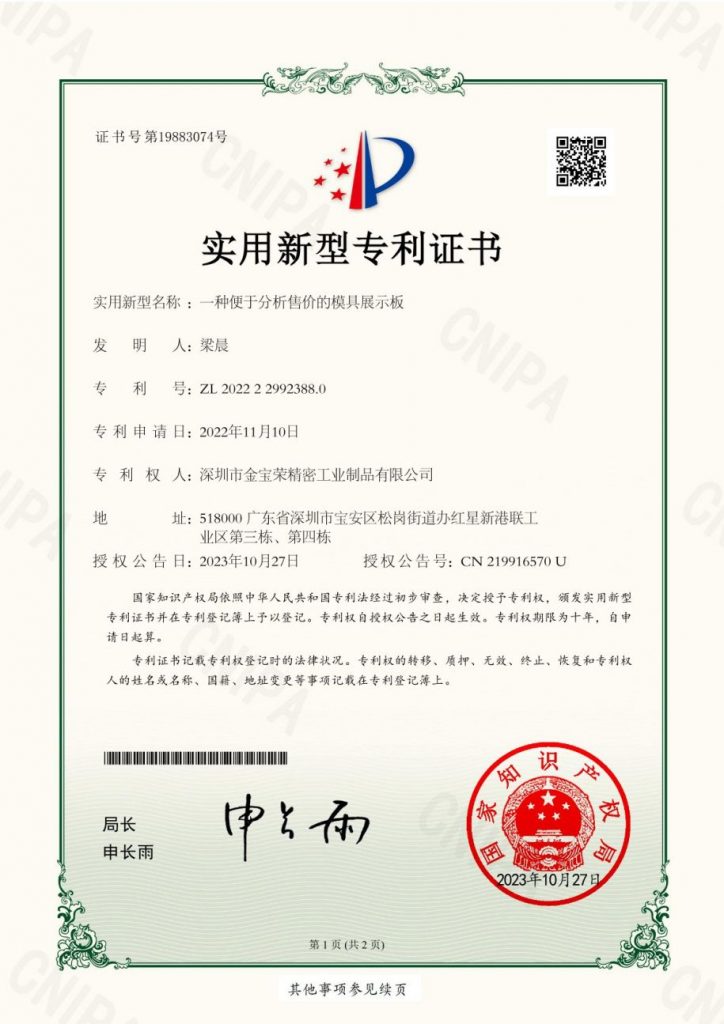

Here are the certifications JBR hold:

By holding these certifications, a plastic injection molding manufacturer demonstrates its commitment to quality, safety, environmental responsibility, and regulatory compliance, giving customers confidence in the reliability and integrity of their products.

This is to certify that JBR (JinBaoRong)Precision Industry Product Co., Ltd, a leading provider of plastic injection molding solutions, has been assessed and found to conform to the requirements of international quality standards. JBR is a reliable and trusty-worthy plastic injection molding manufacturer and an expertise mold making supplier.